Today is an exciting day for Amber Implants! We are proud to announce that our product, the VCFix® Spinal System, has successfully passed all preclinical tests required for the clinical use of the device. These series of preclinical tests are performed according to the new MDR regulations and FDA guidelines for implantable spinal devices.

About VCFix®

The VCFix® Spinal System is the first solution able to treat a broad range of vertebral compression fractures (VCFs) without bone cement. With its 3D-printed perforated structure, the VCFix® implant aims to stimulate bone ingrowth, providing a more natural healing process. It is optimized for mechanical strength, maximum fracture reduction and anatomical restoration. The VCFix® implant provides pedicle anchorage for better stability, better distribution of loads in the middle and posterior columns of the spine, as well the possibility for posterior fixation for more unstable fractures. The VCFix® Spinal System also includes a user-friendly single-use sterile surgical kit for perfect traceability and reduced risks of infection. VCFix® will be the new generation of treatment, providing an easier, more efficient and safer solution for patients with vertebral fractures.

A summary of preclinical Verification and Validation activities

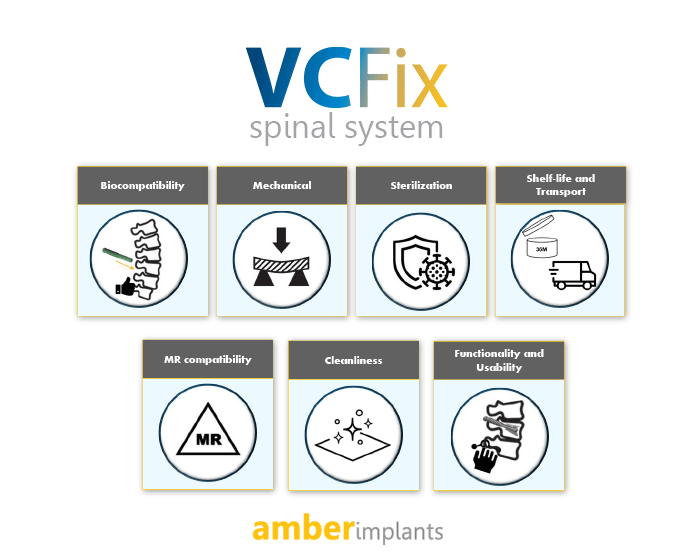

In the development of the VCFix® Spinal System, a risk-based verification and validation plan has been performed. All the verification and validation activities have been designed to mitigate risks by choosing the appropriate representative test articles based on the source of the risk. In this article, an overview of the preclinical tests performed to assess safety and performance of VCFix® (i.e., biocompatibility, animal study, mechanical, functionality, Magnetic Resonance (MR) compatibility, as well as cleanliness, packaging and sterilization) are outlined.

It should be mentioned that all preclinical tests have been performed in compliance with the good laboratory practice (GLP) regulations.

1. Biocompatibility

The biocompatibility evaluation of the VCFix® Spinal System was performed according to the type and duration of contact with the patient. VCFix® implantable components are made of Ti6Al4V ELI alloy that is compliant with a number of recognized international standards and is characterized by an extensive safety history, making it a suitable raw material to control toxicological risks. The VCFix® surgical toolset is mostly made of well-known and biocompatible grades of stainless steel.

Biological safety of the VCFix® implant was evaluated through all the tests suggested by ISO 10993. Based on the test results obtained, the VCFix® Spinal System (both the implant and the toolset) has been proven to be biologically safe and does not pose any toxicological risk to the patient.

For more info on materials suitable for implants and specifically in combination with 3d printing technologies, see our white paper on this topic.

Animal study: As part of biocompatibility validation, to evaluate the local pathological effects of the VCFix® device, an animal study was designed and the protocol was adapted and developed in order to mimic as closely as possible the actual implantation procedure of the VCFix®. Results from the animal study have shown that neither procedure nor device-related issues occured when assessing the performance of the Test Item, i.e., a scaled-down representation of the VCFix® implant in the femur of rabbits. No signs of adverse reactions or infection were macro- or microscopically detected in the tissue surrounding the implanted test articles. Moreover, histological analysis showed that the VCFix® Test Item integrated well with the host tissue, with signs of neovascularization, bone attachment, and bone ingrowth within its porous structure, which resulted in significantly greater osseointegration as compared to the Control Item.

2. Mechanical

The VCFix implant is a combination of a pedicle screw fixation system and an expandable structure. Together, the components ensure secure anchoring of the implant through the pedicles of the treated vertebrae, restoration of the height and angle of the vertebral body, and support of the physiological loading experienced by the spine. Mechanical tests were used to validate the performance of the VCFix® implant under relevant loading conditions applicable to both the expandable and pedicle screw-like structures of the implant. The implant has passed all the tests with outstanding results.

3. Functionality

Functionality tests were carried out on the VCFix® Spinal System to verify its performance when used to treat vertebral fractures in a stand-alone configuration. Several important aspects were investigated in this series of tests, such as the ability of the VCFix® implant to restore vertebral body height and angle after implantation in fractured single vertebral segments, its ability to maintain height and angle of the repaired vertebrae under physiological loading as compared to gold standard treatments for VCF, its stability within the treated vertebral body through assessment of implant subsidence/migration, rotation, or loosening (if any) upon dynamic loading, the effect of mispositioning the implants, and the status of the tissue surrounding VCFix® implants after dynamic loading in single and double vertebral segments. In all these tests, VCFix® has shown great results in treating the fractured vertebrae and maintaining the restored height after dynamic loading.

4. MR Compatibility

To demonstrate MR safety and compatibility of the VCFix® implant, tests following ASTM standards have been performed. Based on the results, VCFix® is MR Conditional and it does not pose any MR-related risks to patients that are scanned with an MR system under the conditions defined on the implant card.

5. Cleanliness

The VCFix® Spinal System undergoes an established cleaning process with the aim of providing a product with physical, chemical and microbial contaminants below a defined level. To ensure effectiveness of the cleaning process and its ability to prevent surface residues from adversely affecting the safety and quality of the product, cleaning validation was performed. Cleaning validation testing outcomes demonstrate that the established cleaning process is effective in reducing all considered contaminants below the defined level.

6. Packaging

Each kit of the VCFix® Spinal System is packed in a sterile double blister sealed with Tyvek and packed in an outer box made of paper. The sterile barrier system, its protective packaging and the associated packaging processes are of critical importance for maintaining sterility of a product up to the point of use. Therefore, the performance and stability of the sterile barrier system are validated according to the estimated life cycle of the product. Packaging validation includes a baseline validation, performance validation, and stability (shelf-life) validation. The test outcomes have demonstrated that the defined sterile barrier system and the process used to create it have been successfully validated. Therefore, the VCFix® sterile barrier system is able to provide a sterile product and to ensure sterility of the product until the point of use.

7. Sterilization

TheVCFix® Spinal System is provided as sterile to users and customers, and the sterilization process is therefore integrated into the supply chain. Sterilization validation tests demonstrated both microbiological safety of VCFix® and sterilization process efficiency. In addition, the bacterial endotoxin method was validated with detected endotoxin levels meeting the acceptance criteria.

These outstanding test results prove the safety and efficiency of the VCFix® Spinal System for clinical use as treatment of patients with vertebral compression fractures. Armed with this fantastic news, we are preparing for the upcoming first-in-human trials.

Interested to know more about VCFix? Please contact us at info@amberimplants.com